Not everyone knows about, or how to talk about vibratory parts feeders.

Here is a terminology cheat sheet.

BASIC BOWL- An untooled bowl consists of a vertical band and a domed bottom with either an external helical track or an internal helical track. The internal track can also be inverted.

ANGLE SKIRT– A conic section, calculated to fit at the required angle, attached between the bottom side of the track and the bowl wall to prevent parts from stacking and causing jams between the tracks.

VIBRATORY FEEDER BOWL– The vibratory feeder bowl is the basic bowl complete with internal or external tooling custom designed to meet feed rate, part orientation and other specifications as required.

ORIENTATION– The correct position of the piece part at the discharge exit as required by the assembly or placing operation.

RATE– The number of parts discharged per minute or hour, as needed to maintain production requirements.

EXTERNAL TOOLING– Any construction outside of the vertical band which separates, orients, selects, confines, or relieves pressure buildup on oriented parts.

RETURN PAN– The structure attached to the outer band for the purpose of re-circulating parts, to the inside of the bowl, that have been rejected by the orienting and selection devices.

FINAL SELECTOR– A tooled section designed specifically to segregate only those parts that are in the correct attitude.

ADJUSTABLE NARROW TRACK SECTION– A short section of interior track that can be set at various widths. The length depends on the size of the part. This can also be an external type. (After exit to the outside of the bowl.) This may be either a stainless or tool steel insert that can be adjusted to either orient or limit parts to a single file.

SWEEP (OR CAM)– A stainless or tool steel insert placed inside or outside the bowl to control the part level or orientation.

FLANGE MOUNT– This is a continuation of the band of the bowl to hold it to the cross arms of the base drive unit. Clamp nuts are used to attach small diameter bowls to the top member. On large diameter bowls, clamp nuts, along with a center bowl, are provided.

CORD SECTION– A straight section of either stainless or tool steel used to select or orient parts. (Can be inside or outside of the bowl.)

BAFFLE– A stainless steel deflector placed on the inside of the bowl bottom to guard the return hole thus allowing parts to flow evenly back up the track from the return pan.

AIR JET– A small diameter tube bolted or welded in place which is sometimes used to assist in moving parts. It is adjusted in the process of development to assist in orientation or final selection with the minimum amount of air pressure.

PARALLEL BLADE SECTION– An area with a stationary or adjustable gap which orients parts (bolts, screws, etc.) to a “hanging attitude”

PRE-ORIENTOR– Properly placed tooling to change the attitude of a part to the proper position for final selection. A per-orientor will generate higher feed rates and minimize re-circulation of the parts, thus extending the life of the bowl, especially with regard to metal or abrasive parts.

BACK PRESSURE RELIEF (OR “BUBBLE”)– An area of the bowl tooling just prior to the entrance to confinement where the parts will buckle if the discharge is full and re-circulate in the bowl. This relieves part pressure which would otherwise cause jamming conditions or miss-oriented parts to bridge across the bowl tooling.

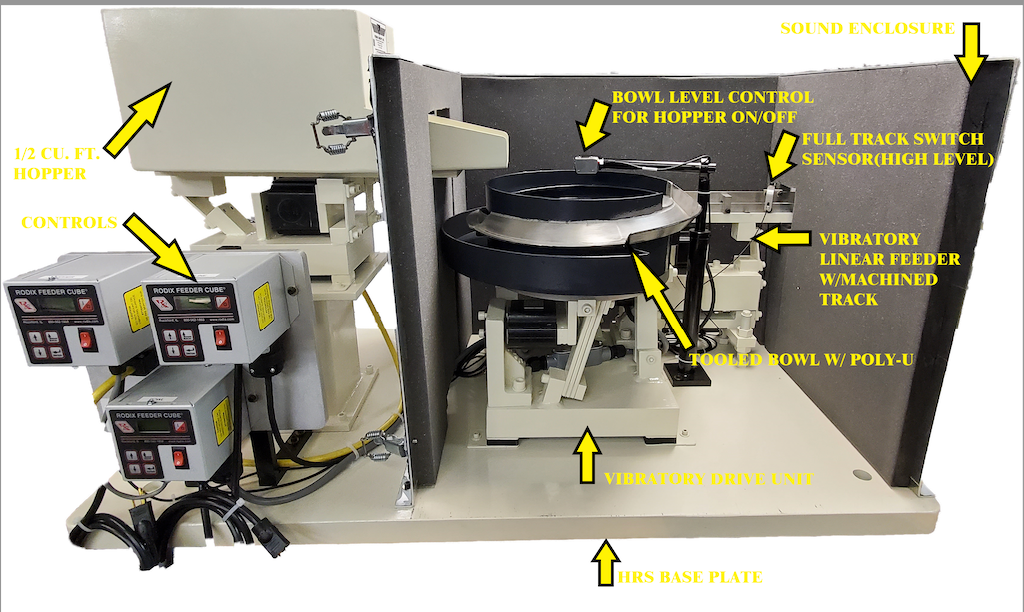

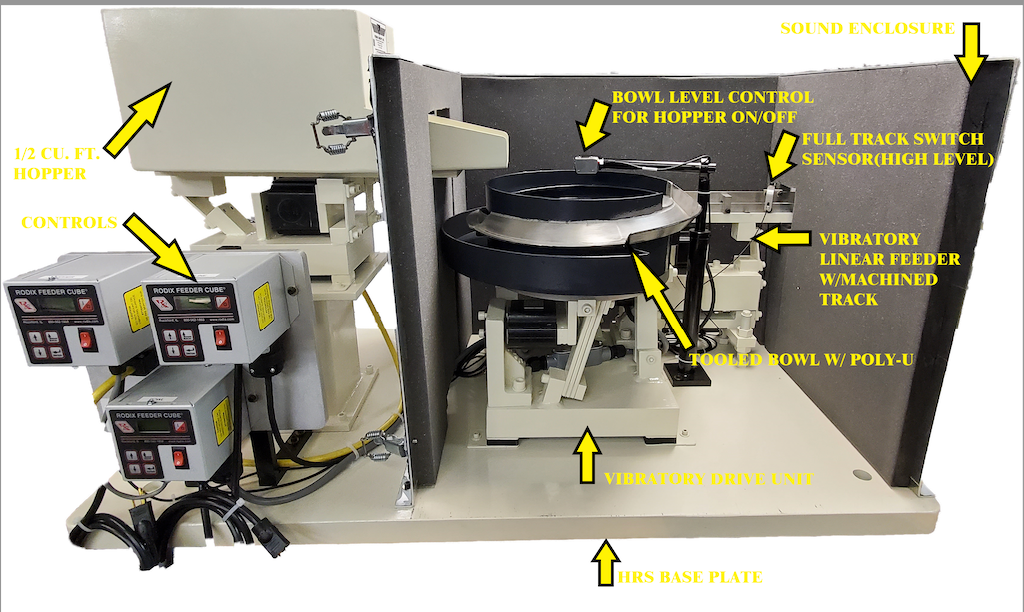

FULL TRACK SENSOR– A means of providing a pressure relief when the parts will not efficiently bubble-off of their own accord. This device can be either a proximity, photo-cell, L.E.D. fiber optic, or pneumatic type sensor to signal the feeder to start or stop. Also a sensor can activate an air jet to eject excess parts from the entrance to confinement, in which case the bowl would continue to run (the latter is most generally used with multiple track bowls).

DISCHARGE CHUTE (HORIZONTAL OR DOWN ANGLE)– short section of track that is mounted tangent to the centerline of the bowl. The discharge chute controls parts in the attitude, or orientation, achieved in the bowl, and , in most cases, conveys them to a horizontal vibratory straight line of gravity track.

CONFINEMENT– A containing section used to control parts through the discharge chute. Confinements are designed in a manner to allow access to the parts by removal of bolted-on sections in most cases.

SCRAP CHUTE– A scrap chute is used to discharge small particles of foreign material from the bowl without interfering with flow of the piece parts.

QUICK DUMP CHUTE– A quick-opening “window” that is provided to facilitate changing from one part to another when multiple styles or sizes of parts are being fed from the same bowl.

RUNNING SURFACE– That portion of the basic bowl, pre-orientor, final selector or discharge chute with which the part makes contact. This is a variable dimension, depending upon the particular piece part.

COUNTER-BALANCE WEIGHT– A solid steel block of predetermined size and weight that is added to the exterior of the bowl. The location is determined on a static counter-balance wheel, in order to off-set the weight of the external tooling, etc.

STORAGE HOPPER– A storage hopper is used to hold extra parts for replenishing the supply in the bowl. Hoppers are set to operate automatically by a signal from a level control switch, thus eliminating either a deficiency or an over-supply of parts in the bowl.

GRAVITY TRACKS– Gravity tracks and vertical magazines are methods of conveying parts. This type track must be set on an angle great enough that gravity will convey the parts from the discharge of the feed system. A magazine is a track in which oriented parts are stacked. This device is usually preloaded; the feeder maintains a full stack.

STRAIGHT LINE VIBRATORY FEEDER– A straight line drive unit is designed to produce linear vibratory motion. It is used to power tracks that convey parts horizontally from the feeder bowl discharge to a dead nest or mechanism.

OVERHANG– Overhang refers to the amount of straight track tooling that extends beyond either end of the inline drive top member.

ESCAPEMENT– A mechanical device placed at the end of the feeder discharge, horizontal straightline, or gravity track to isolate the end part.

PLACING DEVICE (HEAD)– A mechanical means of placing an escaped part into a nest or onto another piece part.